3D Scanning Streamlines Product Development Process

Product development is a process from concept inception to design, development, and commercialization of newly designed products. Its objective is to provide high-quality and innovative products to customers and cultivate, maintain and increase a company’s market share by satisfying consumer demand. It is critical for designers and manufacturers to accelerate product time-to-market and stay ahead of their competitors.

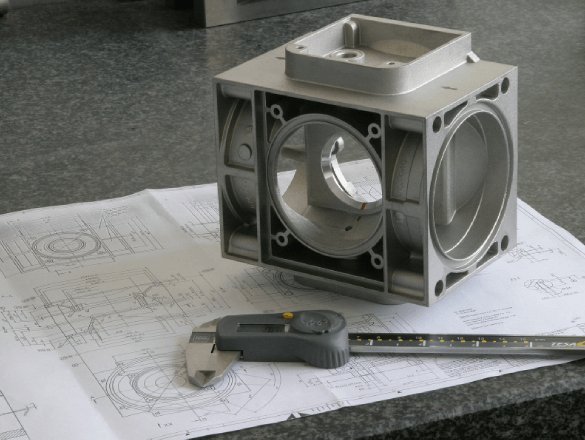

New products start with the understanding of future products and inspirations from designers, a period during which sketches and mockups are made. Then, designers create CAD models to build a prototype. It is time-consuming and laborious to measure with traditional tools such as cardboard and measuring tapes. The measurement results of which usually fail to meet accuracy requirements. 3D scanners, a technology that uses lasers to capture the geometry of parts, can obtain full-filed measurement results precisely in a short amount of time.

How to Enhance Product Development Using a Portable 3D Laser Scanner?

3D Scan

Record mockups of different versions

Generate 3D Models

CAD models for instant viewing and archiving

Revise the Design

Data captured serves as guidance for design revision

First Article Inspection

Verify the first part produced against the original 3D model

Benefits

High-tech 3D scanners capture 3D data efficiently and accurately to reduce costs and increase efficiency during the whole life cycle of product development.

0.00 mm

Max Accuracy

Engineered with sophisticated algorithm, our 3D scanners perform well in capturing accurate 3D data with an accuracy of up to 0.02 mm. It is optimal to ensure that measurement results are as precise as required. These portable 3D scanners are compact and can be carried around with ease to conduct precise measurements without being affected by environmental conditions.

<0 %

Non-destructive

Our 3D scanners are contact-free measuring instruments. By projecting laser beams onto the surface of parts, 3D scanners can obtain point clouds without contacting or altering the objects. They allow designers, engineers, and manufacturers to measure parts without causing damage or destruction. Therefore, no potential harm will be caused to the objects to be measured.

0 +

Applications in Various Industries

Scantech has extensive experience in product development for industries ranging from automotive, rail transport, ship-building, energy, heavy industry, mold to medical. Our handheld 3D scanners are versatile and portable, which can cater to various finishes, materials of industrial parts and complex working environments. You can embrace high-tech 3D scanning to facilitate workflows.

Applications

Automotive

When developing a new automotive prototype, Scantech supports engineers in capturing high-accuracy 3D data on every step of product design to record every modification. Whether it’s a tiny component or a large part, designers can capture accurate and measurable 3D data thanks to the robust algorithm of our 3D scanners.

These 3D data serve as intuitive guidance to fine-tune products to achieve the perfect state. It allows designers, engineers, and manufacturers to speed up day-to-day operations and reduce the time for design significantly.

Rail Transport and Shipbuilding

Product development in rail transport and shipbuilding is challenging due to time constraints, stringent production requirements, and object complexity. It is hard to measure vehicles such as subways and boats, which are usually large.

Scantech’s 3D scanners like KSCAN-Magic incorporates photogrammetry and infrared laser, which suit well for scanning large objects. Our full-range 3D scanner, therefore, can help alleviate challenges in this industry.

Energy & Heavy Industry

With Scantech 3D scanners, non-destructive inspection is truly possible. 3D laser scanning is much faster and more flexible than contact measurement, and it can capture full-field 3D data. It is also possible to obtain the 3D data of curved surfaces, and GD&T of newly designed parts.

3D laser scanners are capable of measuring up to 0.02 mm, ensuring more accurate measurements. It facilitates the design of high-performance machines without compromising on quality standard which saves development costs and shortens development cycles for machinery manufacturers.

Mold

Mold makers process virtual designs into prototypes for testing and approvals and then industrialize them. Handheld 3D scanners are easier and more portable than fixed measurement equipment. It can be used to verify whether the sample meets the original CAD models’ requirements.

Since it is less affected by environmental conditions, it can be used to scan objects anywhere and anytime to reduce the maintenance costs of dedicated laboratories and inspection time.

Medical

Using 3D scanning technology, it is convenient to develop a wide range of products for medical beauty, biomedical engineering, orthopedics surgery, digital dentistry, etc.

Using our handheld and compact 3D scanners such as KSCAN-Maigc, SIMSCAN, and iReal, professionals can obtain complete and accurate 3D data of the scanned object quickly. This precise data can be used to support product development for prosthetics, prostheses, rehabilitation protectors, orthopedic braces, and so on.

Scantech Solutions

<span>Our portable 3D scanners are easy to use and generate precise measurements results, which dramatically accelerates the time to market for newly designed products.</span>

Scantech delivers high-accuracy handheld 3D scanners for engineers to obtain 3D data of the products quickly and accurately. Our 3D scanning technology aids industrial-level designers and project managers in modifying their designs, verify structural rationality, assemble virtually, and debug prototypes. By 3D scanning parts, components or even entire products, users can get accurate and high-precision 3D models in a short amount of time. These models can serve as references for revising mockups and samples. Furthermore, since the full-field geometry are acquired, corrections during the whole stages of product development can be viewed at any time you want.

Product Recommendation

<span>Get the 3D scanner and automated 3D inspection system you need for product development.</span>